The Blog

Articles, videos and stories to help you become a confident PLC programmer and automation professional.

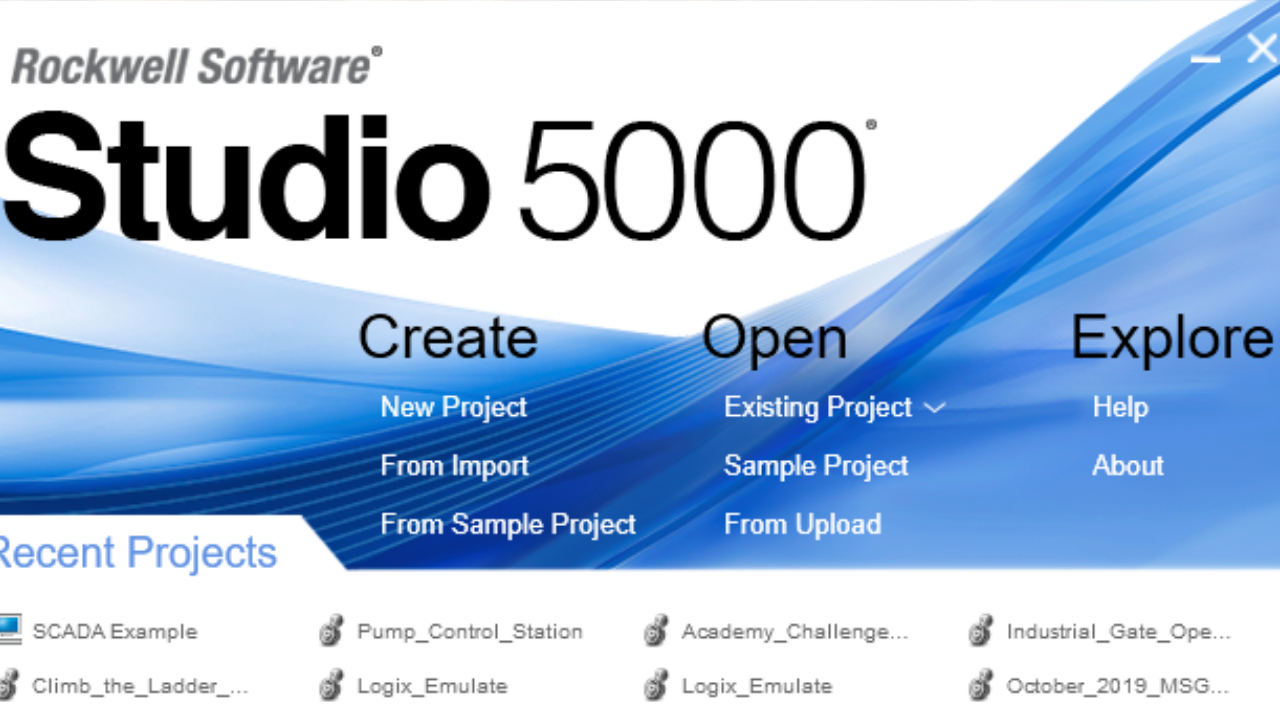

How To Set Up a Studio 5000 Logix Designer Project

This is a quick tutorial on how to set up a Logix Designer project. This lesson and many more on Studio 5000 Logix Designer (and RSLogix 5000) are available inside myPLCtraining Academy.

I hope this helps you get started with RSLogix 5000/Logix Designer. If you enjoyed this lesson, you can learn more from the Become a Confident PLC Programmer course inside myPLCtraining Academy:

Click here to find out more about myPLCtraining Academy.

What did you take away from this lesson? What's one thing you can implement right away? Let us know in the comments below.

VIDEO TRANSCRIPT BELOW

Welcome to Module 2. In this module, we are going to be getting into the nitty-gritty programming stuff that you need to learn to become a confident PLC programmer. As you should know by now, the software we will be spending most of our time on will be Studio 5000, Logix Designer. This is the software you use to program Rockwell's primary PAC platforms, control logix and compact logix.

Here's what...

Beginner's Free PLC Training Part 4 of 4: PLC Ladder Logic

Beginner’s Free PLC Training Series Outline

- Introduction to PLCs

- PLC Processors (CPU)

- PLC Inputs and Outputs (I/O)

- PLC Ladder Logic

When people ask me what I do, I usually say something like “I work as an engineer for an electrical company”. If they are curious enough to ask more, I usually tell them that I do some control system design and a LOT of programming. Most people picture the stereotypical programmer pounding out miles and miles of a text-based language like C++, Java or HTML (dare I say a nerdy?).

I usually try to explain that programming PLCs is different than typical computer programming and how PLCs are used to automate industrial equipment using a graphical-based programming language called Ladder Logic and how I create programs to automate electrical back-up generators and switchgear...then when their eyes begin to glaze over...I realize...I am a nerd after all. But PLC programmers are nerdy in a different way.

You may become nerdy programming PLCs, but once ...

Beginner's Free PLC Training Part 3 of 4: PLC Inputs and Outputs (I/O)

Beginner’s Free PLC Training Series Outline

- Introduction to PLCs

- PLC Processors (CPU)

- PLC Inputs and Outputs (I/O)

- PLC Ladder Logic

Welcome to part 3 of the "Beginner's Free PLC Training" series! Before we get started, if you have not read Part 1 and Part 2 of the Beginner's Free PLC Training series, I recommend that you do that now before continuing this post.

Ok, moving on, in this post we are jumping into PLC inputs and outputs, often referred to simply as I/O. But before we do that, let's do a little review.

In part 1 I gave an introduction to PLCs. We talked about what PLCs are, their history, and how they work compared to a dishwasher.

In part 2 we looked deeper into what the PLC processor does, the relationship between the PLC processor and the human brain, and we looked at a few of Allen-Bradley's most popular PLC/PAC processors.

Now it's time to get a little more specific with what the PLC CPU controls: PLC I/O! In this post we will discuss discrete I/O, analog I/...

Beginner’s Free PLC Training Part 2 of 4: PLC Processors (CPUs)

Beginner’s Free PLC Training Series Outline

- Introduction to PLCs

- PLC Processors (CPU)

- PLC Inputs and Outputs (I/O)

- PLC Ladder Logic

In part 1 of the Beginner's Free PLC Training, I gave an introduction to PLCs. We talked about what PLCs are, their history, and how they work. If you haven't read it yet be sure to start there: Beginner's PLC Free PLC Training Part 1 of 4: Introduction to PLCs.

After you've read that, you're ready to begin this post where we will get a little deeper into the PLC 's Central Processing Unit (CPU) by using the human brain as an analogy and then we will briefly cover some examples of Allen-Bradley PLC/PAC processors.

NOTE: In the industrial automation realm it is common to use the terms processor, CPU or controller interchangeably. So don't get confused when I do that! :)

What is a PLC Processor?

You should remember from part 1 that most of the components of a PLC system can be categorized as one of the following:

- Processor (CPU)

- Inputs

- Outp ...

Beginner's Free PLC Training Part 1 of 4: Introduction to PLCs

If you've been wanting to get into industrial automation and been looking for basic PLC training, but you are not sure where to start, then this Beginner’s Free PLC Training blog series has been written for you!

After you’ve read this 4-part free PLC training series you should be able to identify the primary components of a PLC system and have a basic understanding of the purpose and function of PLCs (and PACs).

When you complete this series, you should be ready to begin learning PLC programming. If you have any questions about this content, please feel free to comment on the post. So, without further delay, let’s jump right into our introduction to PLCs!

Beginner’s Free PLC Training Series Outline

- Introduction to PLCs

- PLC Processors (CPU)

- PLC Inputs and Outputs (I/O)

- PLC Ladder Logic

Programmable Logic Controllers (PLCs) are small industrial computers with modular components designed to automate customized control processes. PLCs are often used in factories and industria...

Intro to Function Block Diagram - Studio 5000 Logix Designer

In this blog post and video, we are continuing to help you toward becoming a confident PLC programmer by introducing the programming language called Function Block Diagram (FBD) inside Studio 5000 Logix Designer...

But before we get into this video, if you want some structured training courses and support to help you become a confident PLC programmer, then check out our membership called, myPLCtraining Academy.

Ok let’s get into this.

Function Block Diagram

This can be really useful when you have multiple machines that all have the same inputs and/or outputs available to the PLC controller.

Check out the video, transcript and screenshots below.

Intro to FBD - Studio 5000 Logix Designer

Prefer to read? Go ahead...

Hey guys, it's Stephen Gates here from myPLCtraining.com, with another video, to help you get confident with PLCs and become a confident automation professional.

This video is going to be all about function block diagram or FBD. And before we get into the video,...

Programming and Automation Made Easy: A myPLCtraining Academy Success Story

myPLCtraining Academy Customer Success Story: Brad Redden

“myPLCtraining Academy is the best value training I have found for programming and automation. Now myself and the guys that I work with are officially trained and have proven knowledge.”

Brad’s Results

- Officially training in PLCs

- Has a training solution for his team

- Saved money over traditional options

- Easy access to reference material

How myPLCtraining Academy helped Brad to update his knowledge on PLC’s and train his team

- Courses that teach from first principles

- Highly responsive support team

- Access to relevant software licenses

- The ability to connect with other technicians in an online community

What were your biggest challenges before myPLCtraining Academy?

My name is Brad Redden, and I am a regional electrical manager. I am in charge of all automation and electrical projects for my company.

I found myPLCtraining whilst searching for a wide ranging training solution for an entry level programm...

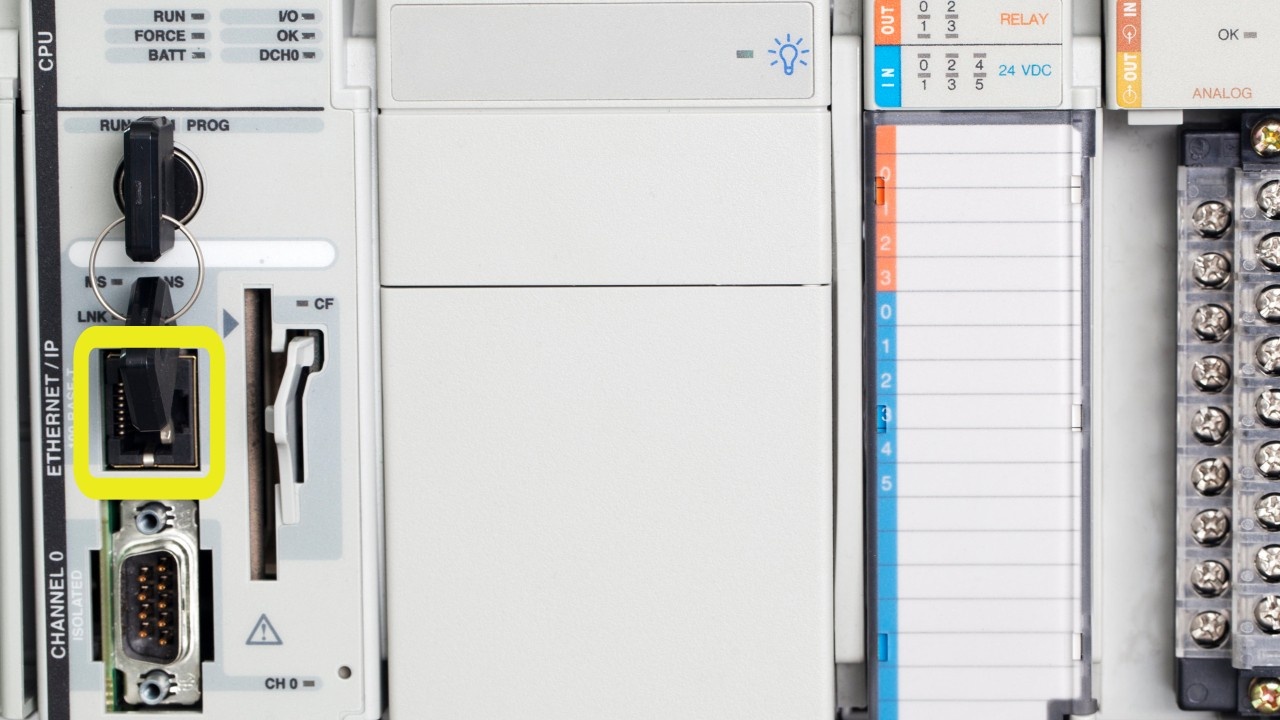

Connecting to Allen-Bradley PLCs - Ethernet

This post is all about connecting to an Allen-Bradley PLC using Ethernet communications.

There are 4 steps you need to take to get your Windows computer talking to an A-B PLC.

Number one, you need to choose and connect some sort of cable between your computer and the PLC. That could be a serial cable or a USB cable with some of the more modern controllers, or it could be ethernet or even something else.

Number two, we need to set up your computer so that it's ready to connect to the PLC. So if you're connecting over Ethernet that means setting the IP address on your computer, or if you're talking over serial or USB, you may need to configure the comm port that you're connected through.

Number three, we're going to set up your PLC for comms and some PLCs are not set up to communicate with your computer out of the box. So there may be some things you have to do with the PLC before you can connect to it.

And then number four, we configure a driver in RSLinx to talk to that specific ...

User Defined Data Types (UDT) in Studio 5000

In this blog post and video, we are continuing to help you toward becoming a confident PLC programmer by explaining a really cool feature in Studio 5000 that allows you to create reusable tag bundles.

I'm talking about User-Defined Data Type or UDTs. But before we get into this video, if you want some structured training courses and support to help you become a confident PLC programmer, then check out our membership called, myPLCtraining Academy. There should be a link below this video, if you’re interested.

Ok let’s get into this.

If you don’t know already there is a really cool feature in Studio 5000 Logix Designer called User-Defined Tags (UDT). This feature allows you to create “bundled” tags into one tag and then reference each of the bundled tags as members of the single main tag.

This can be really useful when you have multiple machines that all have the same inputs and/or outputs available to the PLC controller.

Check out the video, transcript and screenshots below.

U...

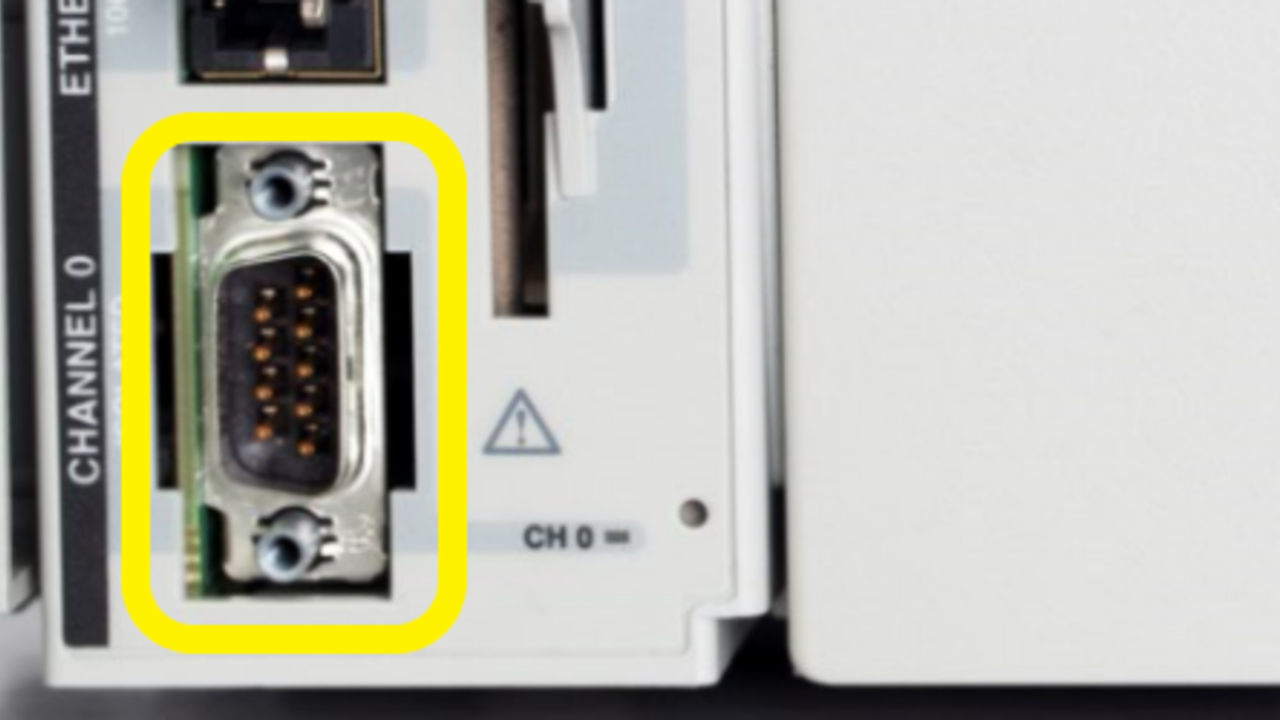

Connecting to Allen-Bradley PLCs - DF1

This article is all about connecting your computer to Allen-Bradley PLCs with serial communications. Particularly, the DF1 serial protocol from A-B.

The DF1 protocol is usually used when you connect a RS-232 cable from your computer to a PLC. The typical RS-232 cable uses a 9-pin connector as shown below:

Now, to be honest, A-B doesn’t even make PLCs with serial ports anymore. Most newer PLCs have a USB port and an EtherNet/IP port. But there are still a lot of older PLCs out there that have a serial port so this training will probably come in handy for you at some point ;)

Plus, having a good understanding of how to set up communications from your PC to your PLC with the serial protocols will help when you need to use other communication options such as Ethernet and USB.

So, if you remember from part 1 of this series (back in December 2019), there are 4 basic steps to connecting to any Allen-Bradley PLC:

- You need to choose and connect some sort of cable between your computer a...