The Blog

Articles, videos and stories to help you become a confident PLC programmer and automation professional.

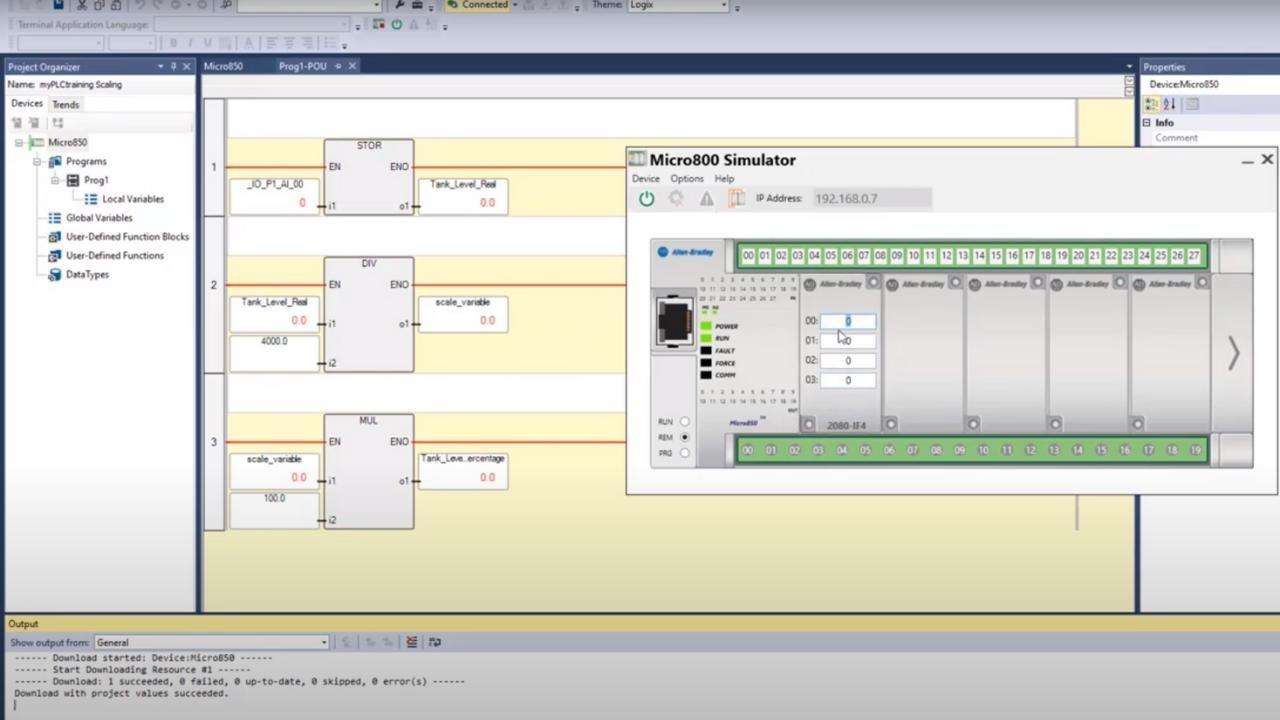

Connected Components Workbench (CCW) - Math Instructions in Ladder Logic

This post is all about using Ladder Logic for programming in Connected Components Workbench.

If you are new to Connected Components Workbench, I'd encourage you to check out the intro to CCW post here.

Specifically, we are going to take a look at using math instructions in Ladder Logic to do calculations within CCW.

For example, let’s say we wanted to track the liquid level in a tank as a percentage. In many cases, the analog input for a tank level sensor might be scaled such that it shows the gallons of the tank.

So if it’s a 4,000 gallon capacity tank with a 4-20mA sensor, the analog input may already be scaled such that the PLC analog input tag sees the 4-20mA value in terms of 0-4000 gallons, which is good. But, sometimes you just want to work with simple percentages.

So we could do a simple calculation to convert the 0-4000 gallon value into 0-100%

In other words, scale the value again to convert from gallons to percentage.

The calculation is simple enough:

Analog_Inpu...

Studio 5000 Logix Designer - Comparison Instructions

Comparison instructions are important for handling analog inputs into your PLC. Check out how to use the basic compare instructions and some cool things you can do with them!

This is just a sample of the type of training you'll learn from myPLCtraining Academy and the Confident PLC Programmer Method...if you want to know more if you need to start with a little basic stuff before getting to comparison instructions then we have the perfect training method for you. Click below to learn more.

The Confident PLC Programmer Method

Enjoy and I'll talk to you again soon!

Stephen

VIDEO TRANSCRIPT BELOW

Hey guys, it's Stephen with myPLCtraining.com and today I'm going to do a quick video on how to set up and use comparison instructions in Studio 5000 Logix Designer.

If you're wanting to start creating better PLC programs that handle analog inputs or you just want to be able to understand and troubleshoot existing PLC programs better, then this video will help you get there and if you'r...

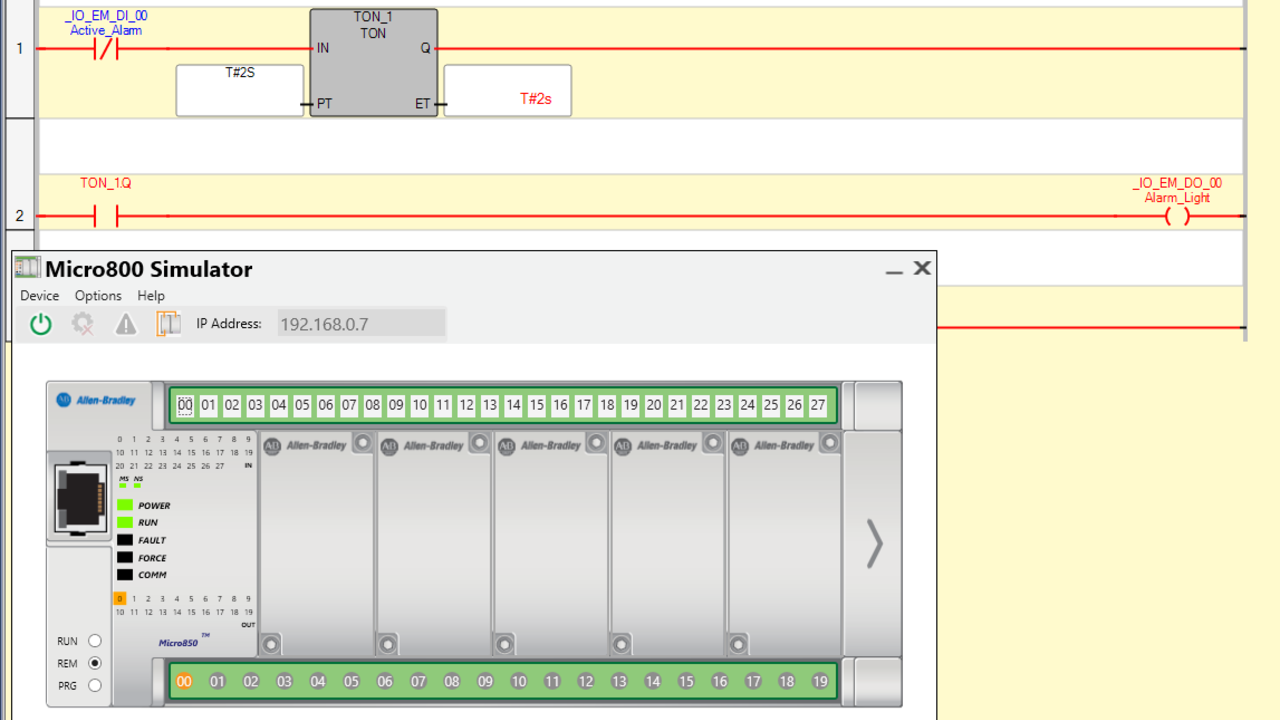

Connected Components Workbench - Using the PLC Simulator

In this article we get into how to use the built in PLC simulator/emulator inside Connected Components Workbench (CCW).

Let's get into it!

The CCW software is free at least the standard version is. And it's becoming more and more popular in Industry around the world for a few different reasons.

For one thing the controllers that you can program with this software are very inexpensive. The controllers are the Micro800 series controllers from Rockwell Automation Allen Bradley. And I believe they are all available for less than $1,000.

Many of the controllers come with built-in IO which is another cool feature that saves money and configuration work. so4 smaller automation projects the CCW software and the associated Micro 800 controllers are often a great fit.

Another cool thing about this software is that it can also be used to program HMIs and drives that would be used in conjunction with the Micro800 controllers

One thing that is disappointing about the software is...

How to Get a Job as a PLC Programmer

“How do I get a job as a PLC programmer?”

I get this question a lot from my readers and students.

Unfortunately, there isn’t a simple answer to this question. But, the good news is that it is very doable for many motivated electricians and technicians to make the move to PLCs, automation and controls.

And if you’re a mechanical, electrical or chemical engineer, it’s probably going to be even easier.

Ok, so what does it take to get a PLC programmer job?

Here are 4 things that I think you should focus on:

- Get involved in automation related equipment and projects at your current job (if there are any)

- Making friends/connections with PLC programmers, automation technicians and automation engineers

- Get good at solving problems in your current job

- Learning PLC-related skills on your own time/dime (if you’re company won’t pay for it)

Ok, there you go! Thanks for reading.

Bye!!

Oh, you want to know more?

Ok, ok. I break down the 4 things you should focus on in detail in the vi...

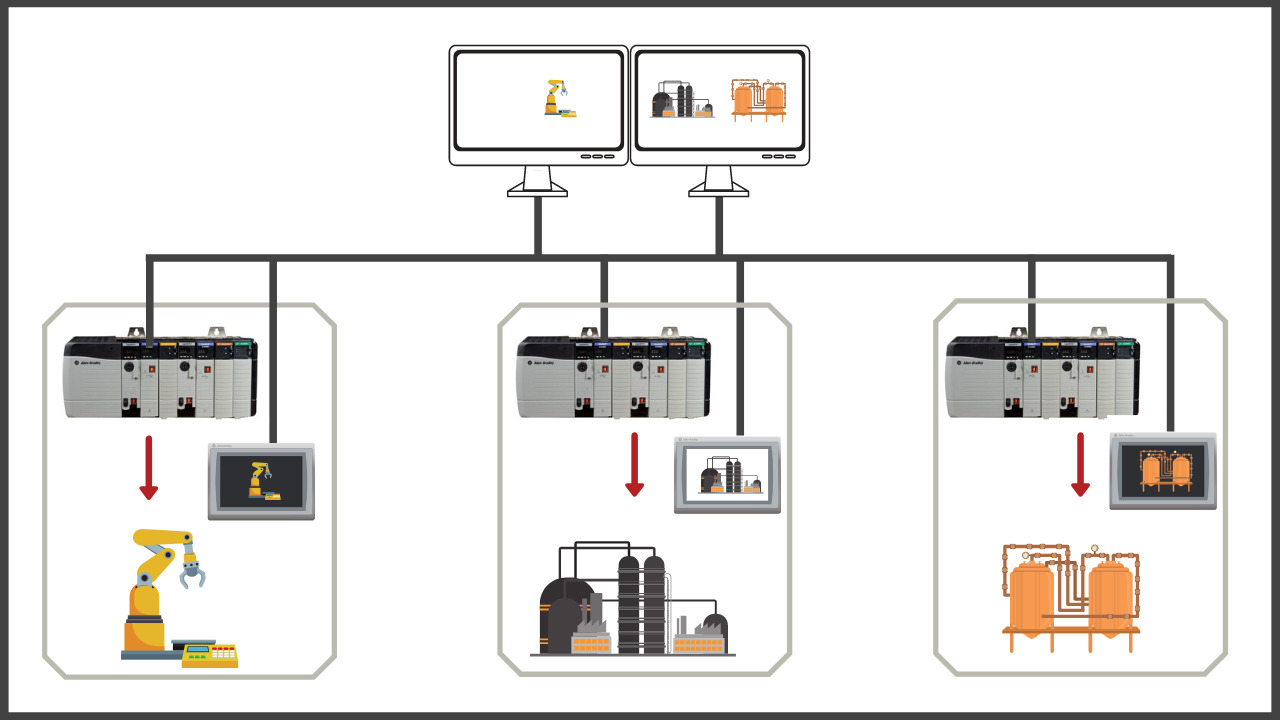

What is SCADA?

This blog post is all about SCADA.

Ever heard of it?

SCADA stands for Supervisory Control and Data Acquisition.

It’s basically a computer-based system that provides basic control and detailed monitoring of plants and industrial equipment.

The industries where you’ll these systems called SCADA are usually: telecommunications, power and energy, water/waste-water and oil and gas refineries.

On a basic level, a SCADA system is just an Human-Machine-Interface (HMI) (or multiple HMIs) with connections to various automation controllers such as PLCs or monitoring devices such as power meters or anything else that provides monitoring of plant equipment.

All these devices work that control and monitor the plant equipment.

Power Plant SCADA

In a system like a power plant, the SCADA would give operators a zoomed-out. overall view of the plant. This would include the power generators, circuit breakers, transformers, switchgear and more.

You’d be able to see things like: the status of the g...

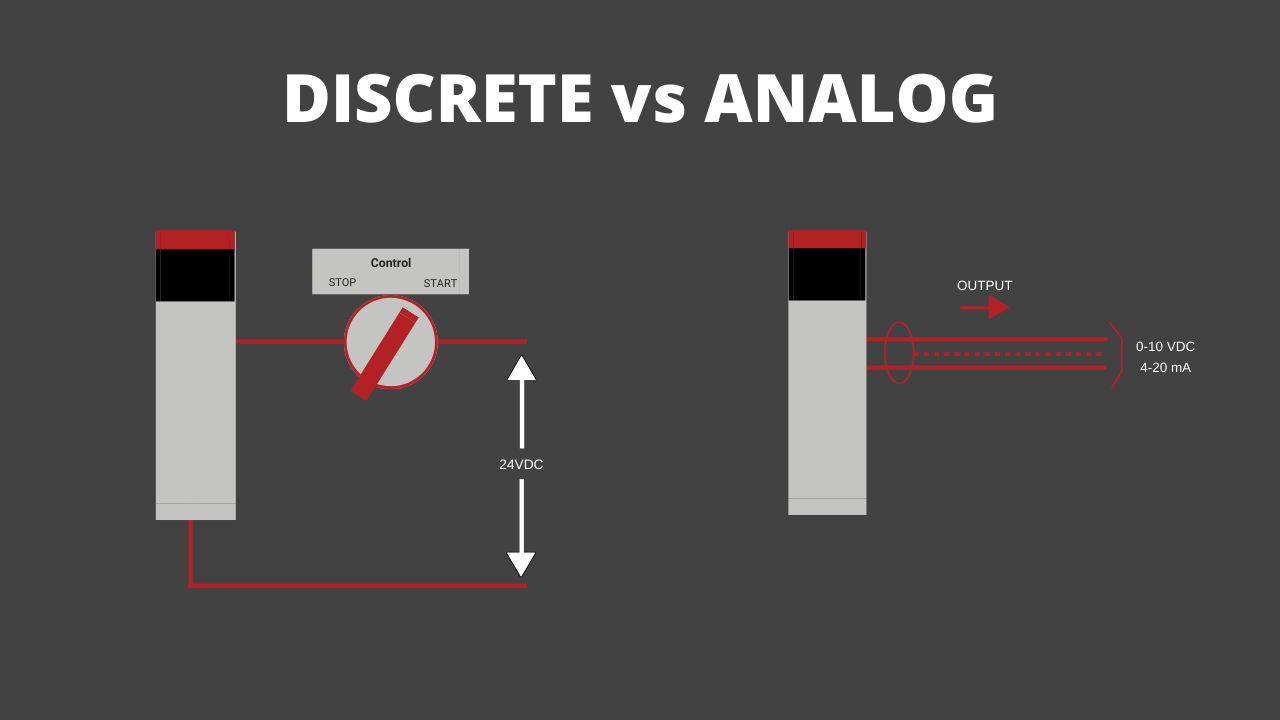

Discrete Vs. Analog I/O

This month’s topic is Discrete I/O vs Analog I/O.

If you’ve delved into PLCs at all, you should know what PLC inputs/outputs (I/O) are. But here’s a quick refresher...

PLC I/O is the part of the PLC that connects the brain of the PLC (the CPU), to the outside world, the machines, the switches, the push-buttons, etc. In a PLC system there will usually be dedicated modules for inputs and dedicated modules for outputs.

An input module detects the status of input signals such as push-buttons, switches, temperature sensors, etc.. An output module controls (turns on/off, ramps up/down, etc.) devices such as relays, motor starters, lights, gauges, etc.

Discrete/digital I/O is either on or off (think light switch on or off). Analog I/O can be on or off or in between (think light switch dimmer).

The inputs tell the PLC what to do with the outputs (depending on how you've programmed the logic).

We are all familiar with computer I/O (you're using it right now). For instance t...

Connecting to Allen-Bradley PLCs - Introduction

One of the questions I get a lot, is how to connect from your computer to a PLC. This is foundational to getting confidence with PLCs, so I decided to make short video series to show you how to get it done.

This video will walk you through the basics for communicating with ANY Allen-Bradley PLCs.

CONNECTING TO ALLEN-BRADLEY PLCS INTRO

Prefer to read it? Go Ahead…

Hey there guys, it's Stephen Gates with my PLC training.com with another video here to help you become a confident PLC programmer.

So one of the biggest questions or most common questions I get from people is how to connect from their computer to a real PLC so they can download or upload the program or just go online and see what the controller sees. So I'm going to do a short video series on the steps on what you need to connect your computer to an Allen Bradley PLC. So let's jump right into it.

So before we get officially started, I wanted to let you know about a free cheat sheet I have where I can show y...

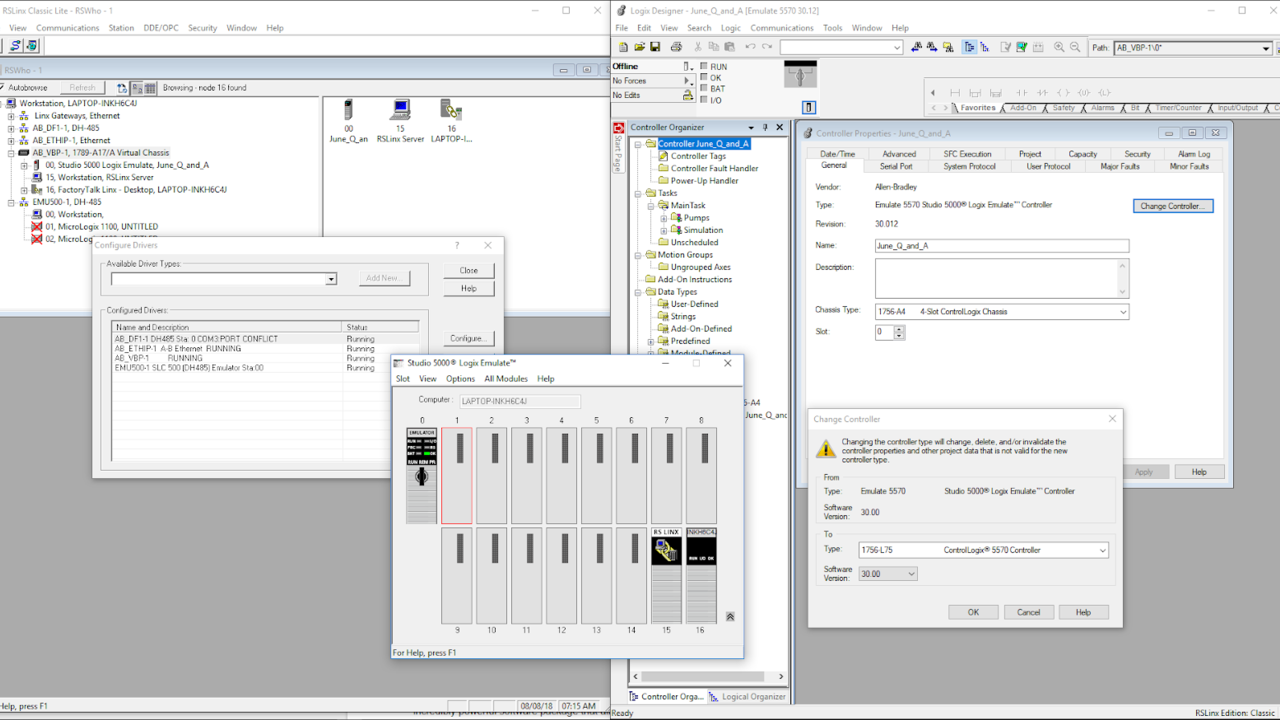

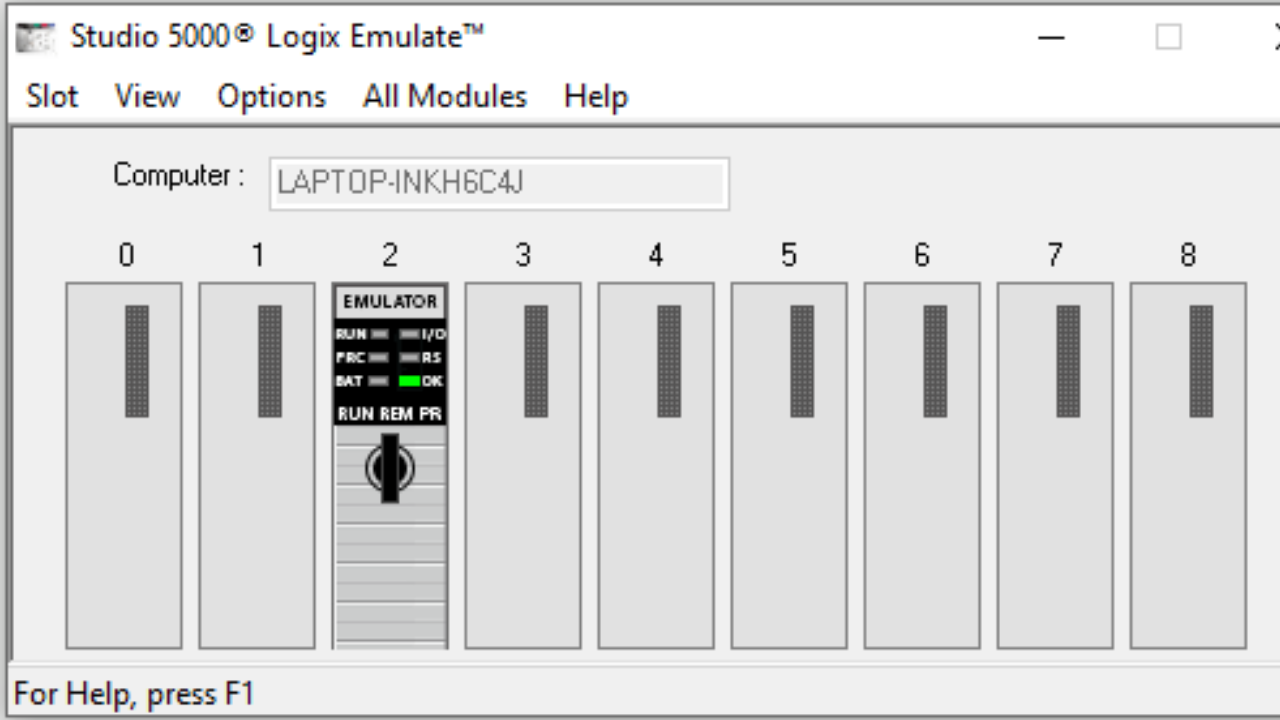

Studio 5000 Logix Emulate

This month we have another PLC training article to help you become a confident PLC programmer

The theme is…

Studio 5000 Logix Emulate

This software is key if you want to learn/practice Allen-Bradley PLC programming anytime and anywhere and don’t want to have to buy an expensive PLC to lug around (granted the software is expensive too, but I have a solution for that ;)).

This tool is extremely valuable and will even help you with testing, simulating PLC logic for real projects.

Here’s how it works:

Logix Emulate gives you the ability to turn your computer into a PLC. So it takes a chunk of your computer’s power and makes it function almost exactly like a ControlLogix PLC controller, such as the 1756-L71 controller.

I think this is one of THE best tools for helping you learn PLC programming and that’s why we include access to this software in myPLCtraining Academy. But more on that later…

Setting up a Studio 5000 Logix Designer project for a Logix Emulate contr...

Messaging - How to Get A-B PLCs to Talk to Each Other

This month’s blog post topic is all about sending messages between PLCs. Specifically Allen-Bradley PLCs, such as ControlLogix and CompactLogix controllers.

This is actually pretty cool and a fun topic to learn.

Here’s a simple example of why you’d want to communicate data from one PLC to another.

Let’s say PLC 1 controls one steam boiler and PLC 2 is the main plant PLC that monitors the alarms all the boilers in the plant and other equipment as well.

Think of PLC 2 as the Plant SCADA PLC that allows an operator in the main control room to get an overall look at the plant from his control room.

So let’s say we want to send data from PLC 1 such as the most important boiler temperatures and pressures so that we can display them on the control room HMI screen.

If these are Allen-Bradley PLCs (ControlLogix, CompactLogix), the best way to do this is usually to use Ethernet. Specifically EtherNet/IP.

Here’s a simple image of how the two PLCs would likely be physically...

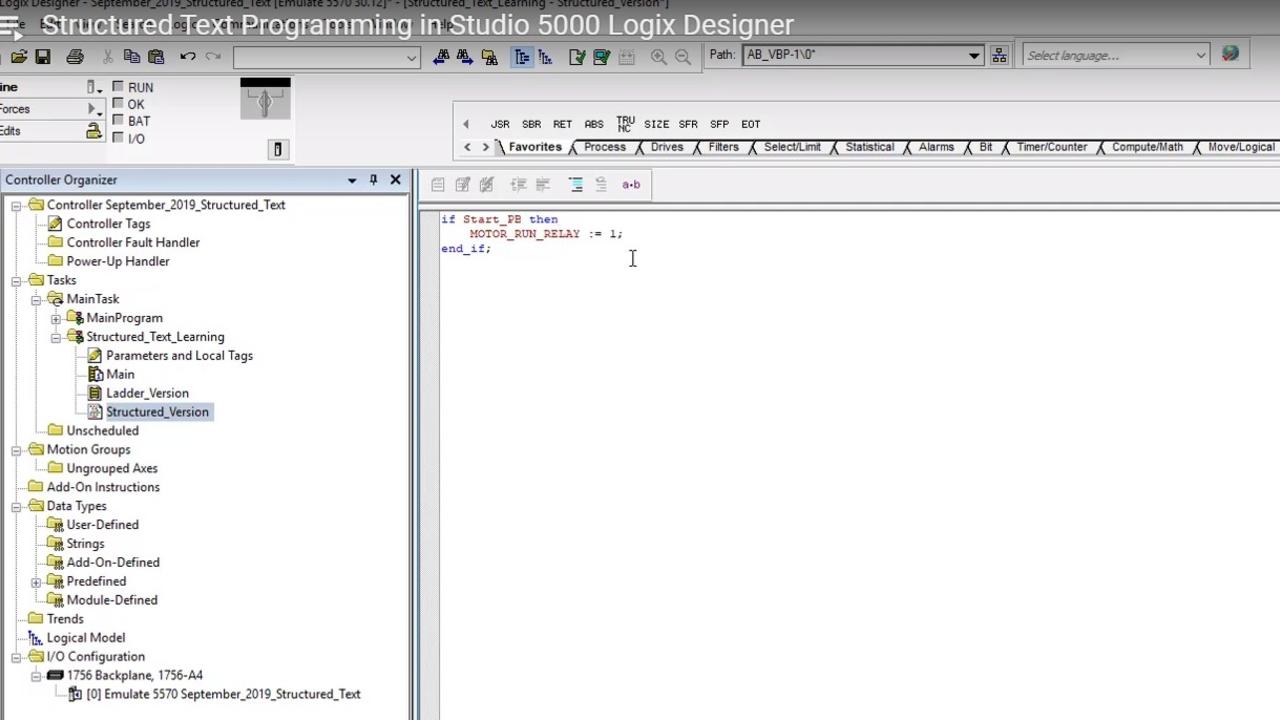

Learn Structured Text

I’m excited about the topic of this article, which is….

Structured Text!

Structured Text is an up and coming, popular programming language used in PLCs. This language is much different than ladder logic but it allows you to do all the same things and more with a lot less space (visually and in terms of processor memory).

It’s been around for a while but it’s getting really popular now, so it will serve you well to at least have a basic familiarity with it.

It’s actually a lot like other more traditional programming languages out there like C++ or Java but it’s specifically designed for PLCs.

Here’s an example of a really simple Structured Text program in an Allen-Bradley PLC (Studio 5000 Logix Designer):

IF Start_PB THEN

Motor_Run_Relay := 1;

END_IF;

IF Stop_PB THEN

Motor_Run_Relay := 0;

END_IF;

The logic above turns on the Motor_Run_Relay output when the Start_PB input is on (being pushed) and it turns off the Motor_Run_Relay output when the Sto...